Precious Metals

Precision gold casting involves melting gold alloys and pouring them into a Graphite & Wax mold to create intricate jewelry and other high-value items.

Global Graphite offering High density Graphite which having high thermal conductivity, and durability, make it an ideal material for various components in the precision gold casting process.

These graphite parts ensure consistent quality, dimensional accuracy, and integrity in the final gold products.

Graphite heaters provide uniform and controlled heating within the casting equipment, ensuring precise temperature regulation critical for melting and shaping metal alloys like gold. Their high thermal conductivity guarantees consistent heating, preventing hot spots and ensuring homogeneous melting.

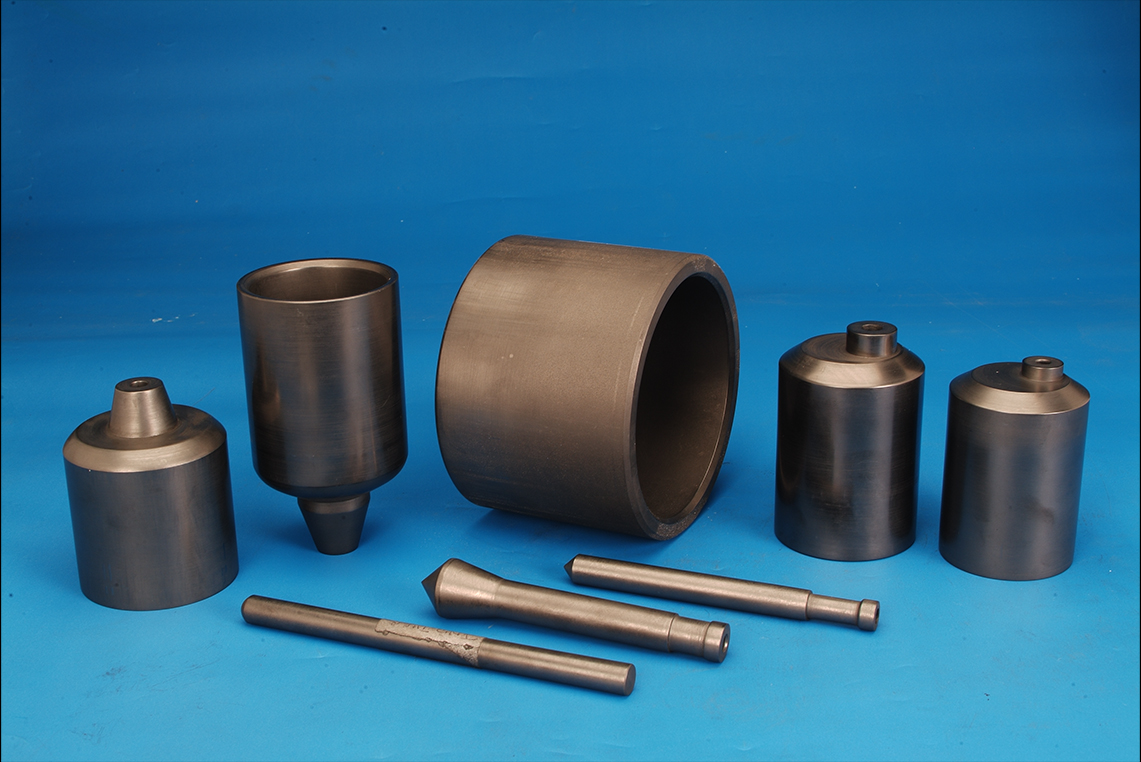

Graphite crucibles serve as containers for melting and pouring the molten metal alloy. Their excellent thermal shock resistance and chemical inertness make them ideal for withstanding the extreme temperatures and corrosive environments encountered during gold casting.

Graphite molds are used to shape the molten metal alloy into the desired form during casting. They offer superior dimensional stability, allowing for intricate designs and precise replication of details, essential for high-quality gold castings.

Graphite rods facilitate mixing and homogenization of the molten metal alloy, ensuring uniform composition and properties throughout the casting process. Their high strength and thermal stability enable efficient stirring without risk of contamination.

Graphite insulation materials provide thermal insulation within the casting equipment, minimizing heat loss and optimizing energy efficiency during gold casting operations. This helps maintain stable temperatures, enhancing process control and product quality.

Email us to Get a Free Estimate