Diamond Tools Sintering

Is A process for manufacturing tools like Saw Blades and Drill Bits & Wire Saw Tools. It Involves mixing diamond particles with a Metal Binder and Compacting them In a Graphite Molds Under Pressure & Temperature.

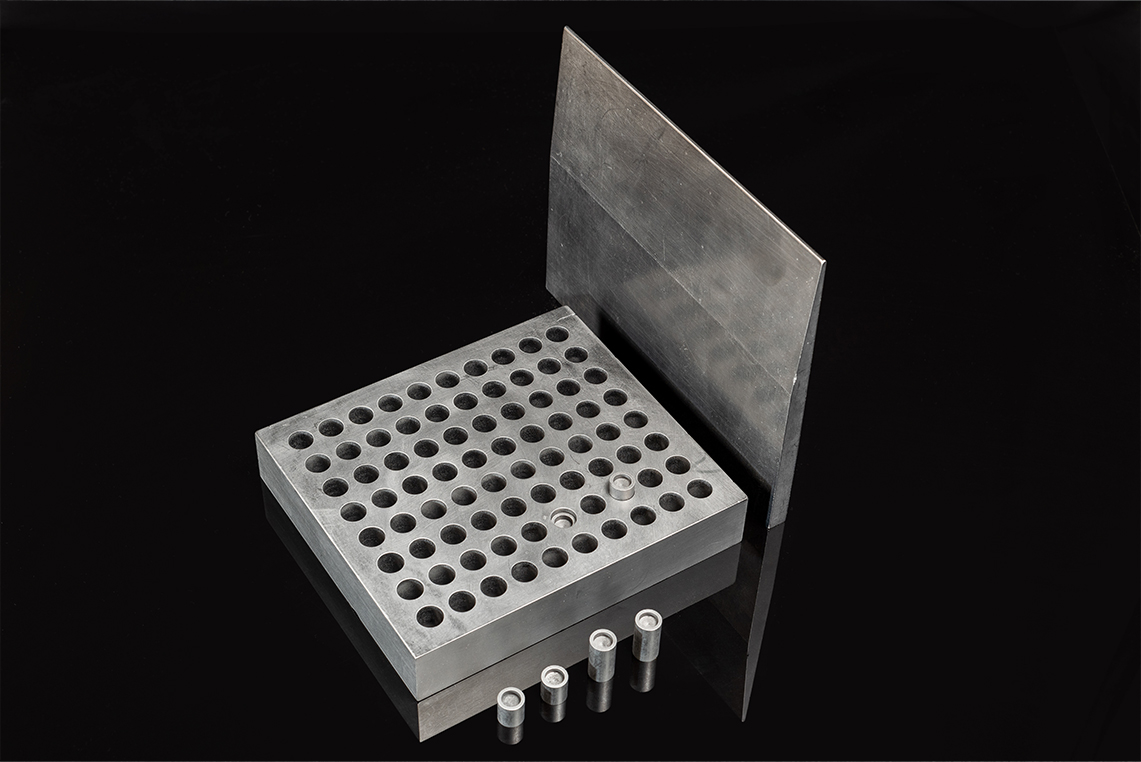

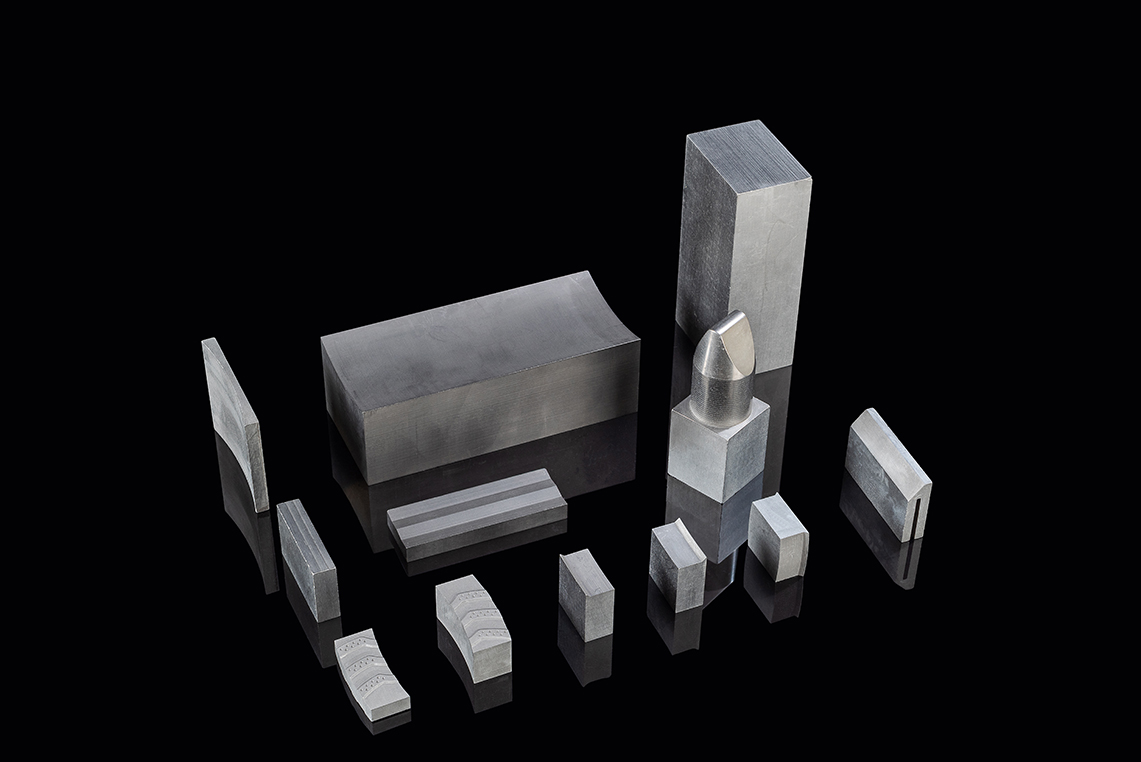

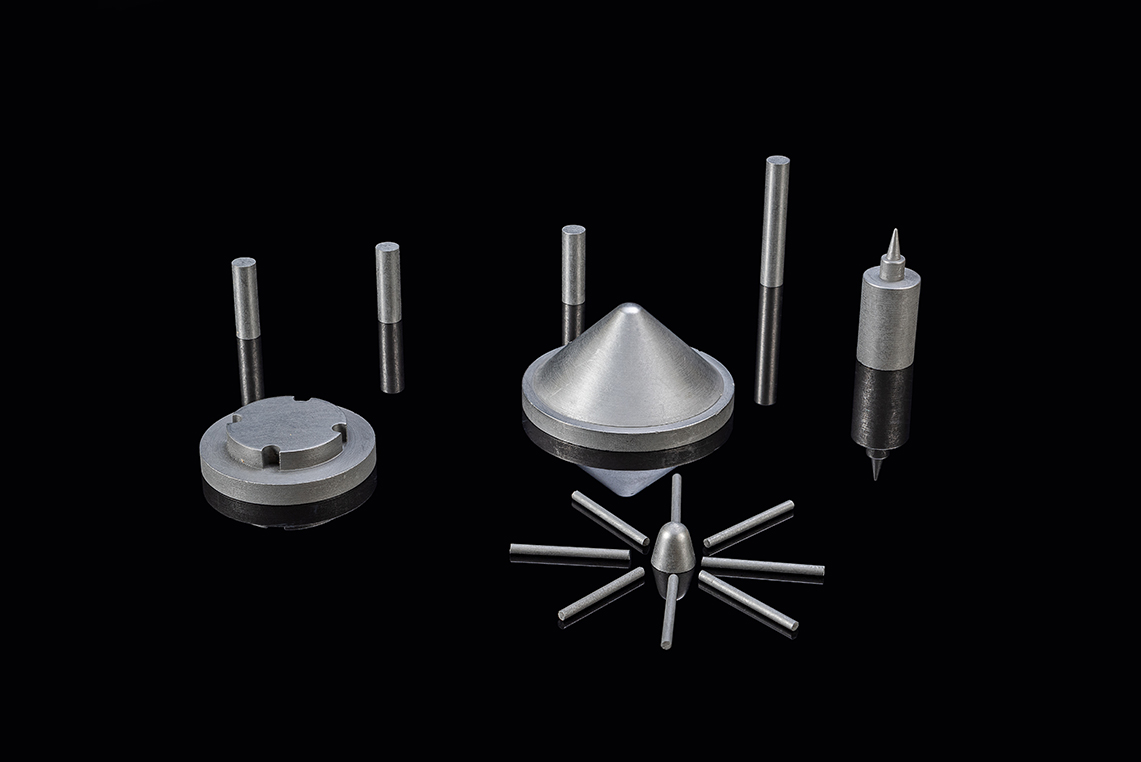

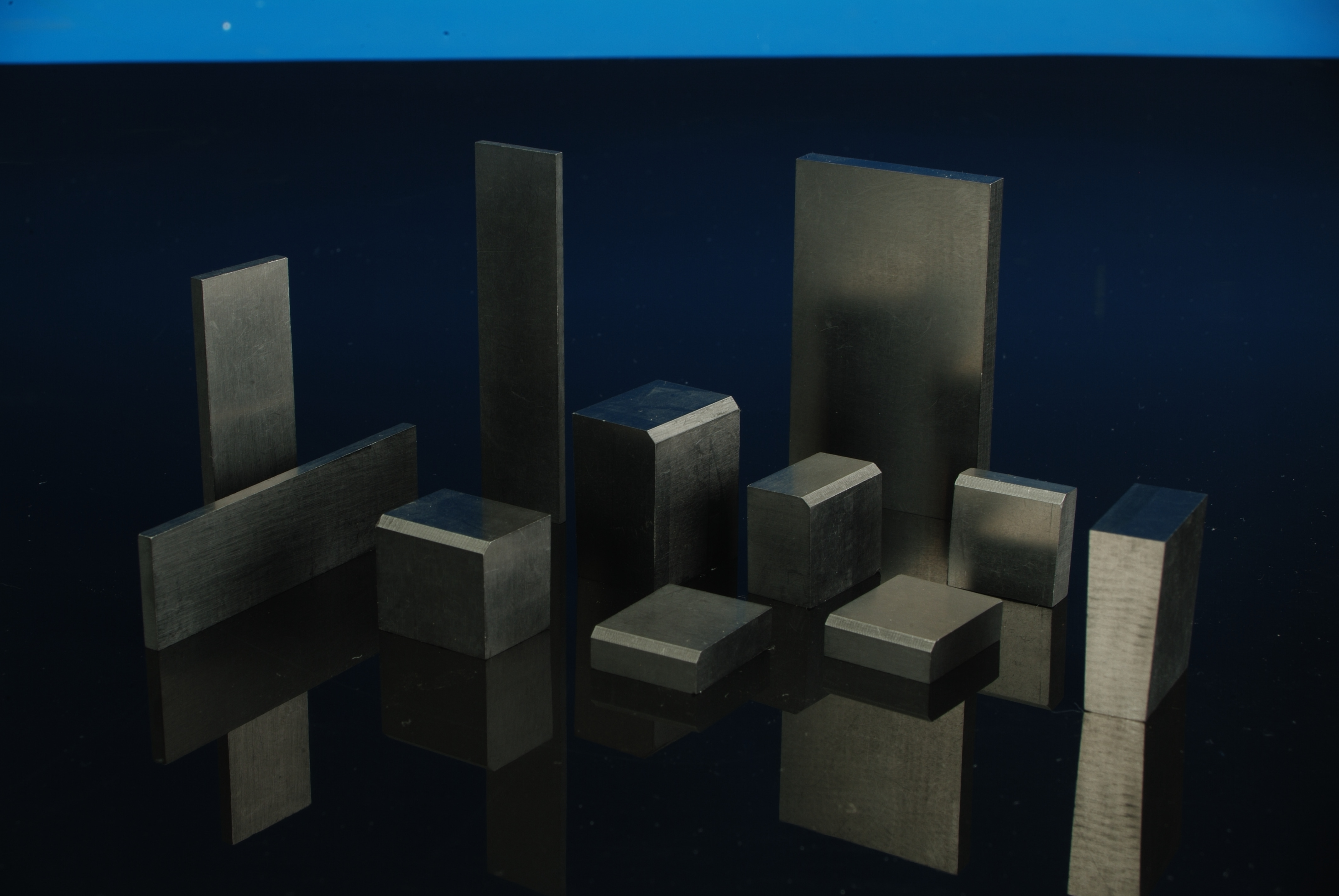

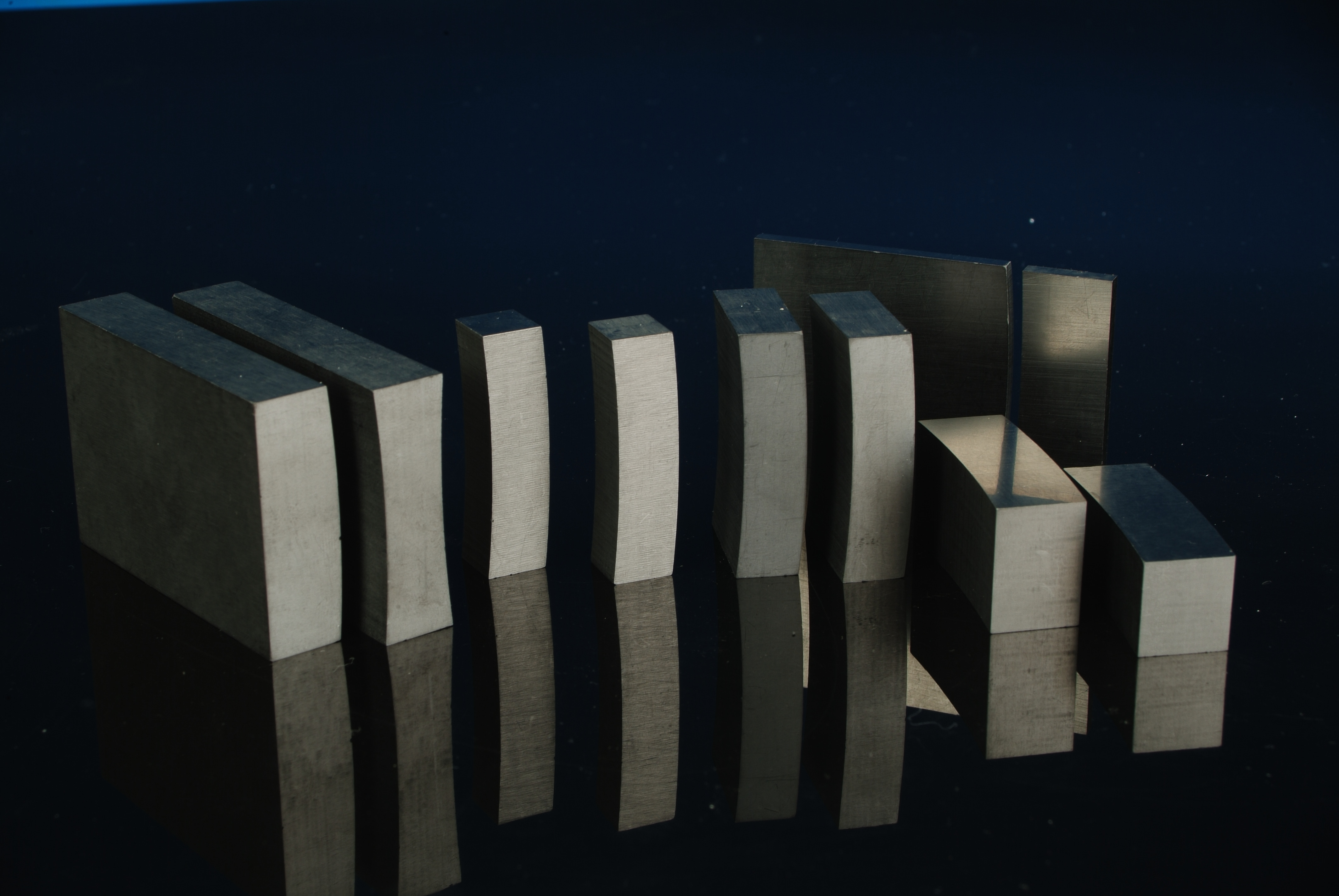

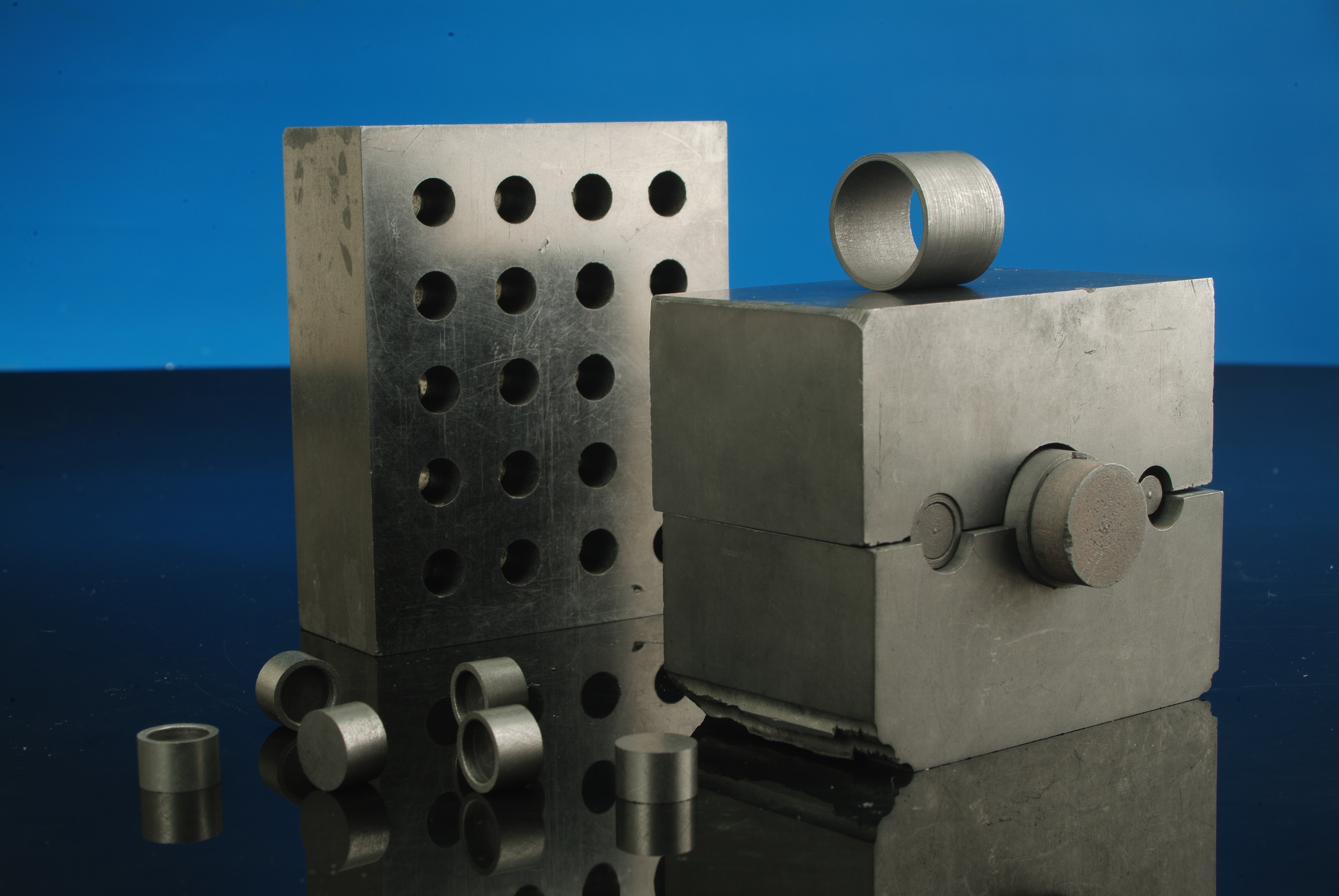

The Process begins with Preparing Metal Powders and Diamond Grits, Which Are Mixed With A Binder. These Materials are then Poured Into a Graphite Mold Cavity. Graphite Punches And Side Graphite Plates are used to Compact the Powders Evenly within The Mold, Ensuring Density and Eliminating Voids.

Once Compacted, the Filled Mold undergoes Sintering In a Furnace. The Temperature Is Raised Below The Melting Point of The Binder, Causing The Metal Particles to Fuse Together, Creating a Solid Matrix that holds The Diamond Grits.

After Sintering, The Mold Cools, and The Graphite Components are Removed, Revealing The Finished Diamond Tool.

Graphite Molds offers High Thermal Conductivity, Aiding Efficient Heating And Cooling During Sintering. Punches And Side Plates Ensure Uniform Pressure Application, Resulting In Consistent Tool Quality. Overall, Graphite Components are Integral to The Precision and Reliability Of Diamond Tool Sintering Processes.

Global Graphite Offering High Density Graphite Mold Parts Like – Graphite Side Plates ,Graphite Electrodes, Plungers , Punches , Separators ,Bush Etc. With Superior Graphite Quality, close Tolerances, high Accuracy & Customized Graphite Parts As Per Customer Drawing & Specifications.

Made in India, Made for the world.

Email us to Get a Free Estimate