Continuous casting of copper and copper alloys process

Involves feeding molten metal through a water-cooled graphite mold to produce long, uniform strands or billets.

The metal solidifies as it passes through the mold, resulting in a continuous production process.

This method offers high productivity, improved product quality, and energy efficiency. Once solidified, the metal is extracted and cut to the desired length for further processing.

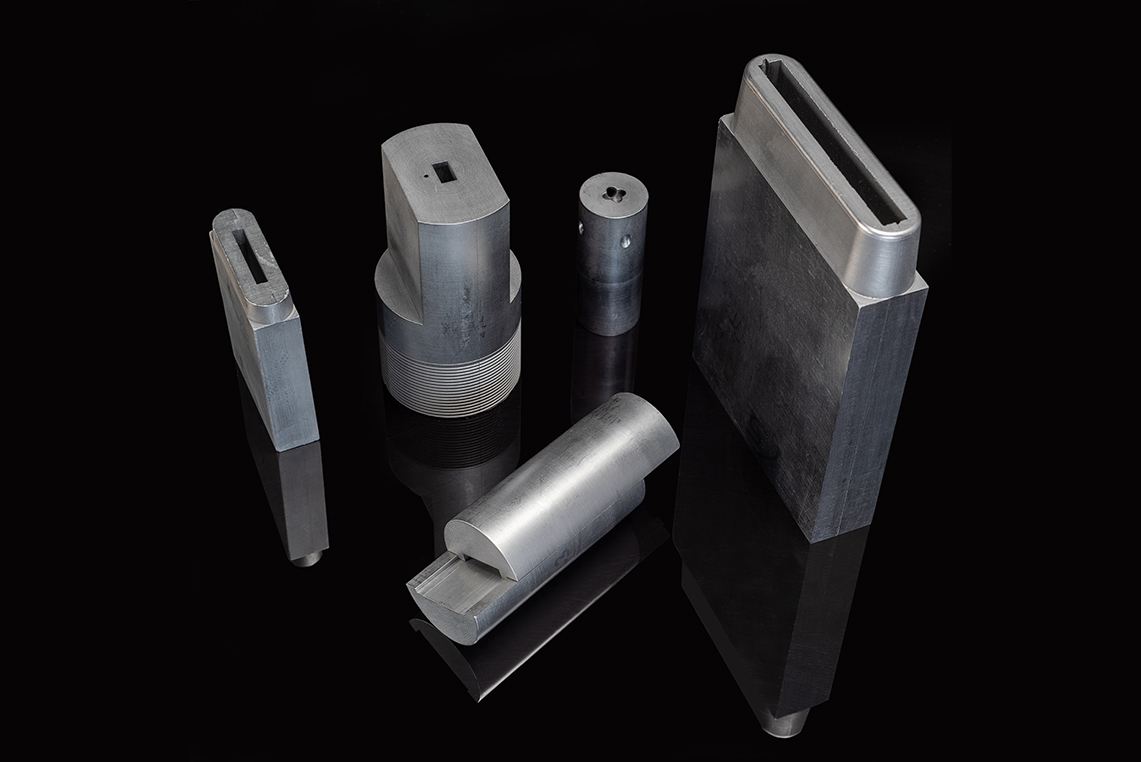

Graphite are essential tools in the casting industry, providing high thermal conductivity and excellent resistance to thermal shock. They play a vital role in achieving precise casting dimensions and surface finish.

Global Graphite offer High density Graphite die-set which is wear-resistant graphite materials extend die lifespan, minimizing downtime and replacements. And high thermal conductivity in graphite aids in rapid heat absorption and dissipation during casting, ensuring uniform cooling. with Smooth graphite die-set surfaces contribute to a high-quality finish on the continuous cast products, reducing the need for additional treatments.

Our High accuracy of Machined Graphite dies play a key role in achieving accurate and consistent dimensions in continuous cast materials & production output.

We offer Customized Graphite die-set as Per Customer Drawing & Specifications.

Email us to Get a Free Estimate