Aluminium Nitrogen Degassing

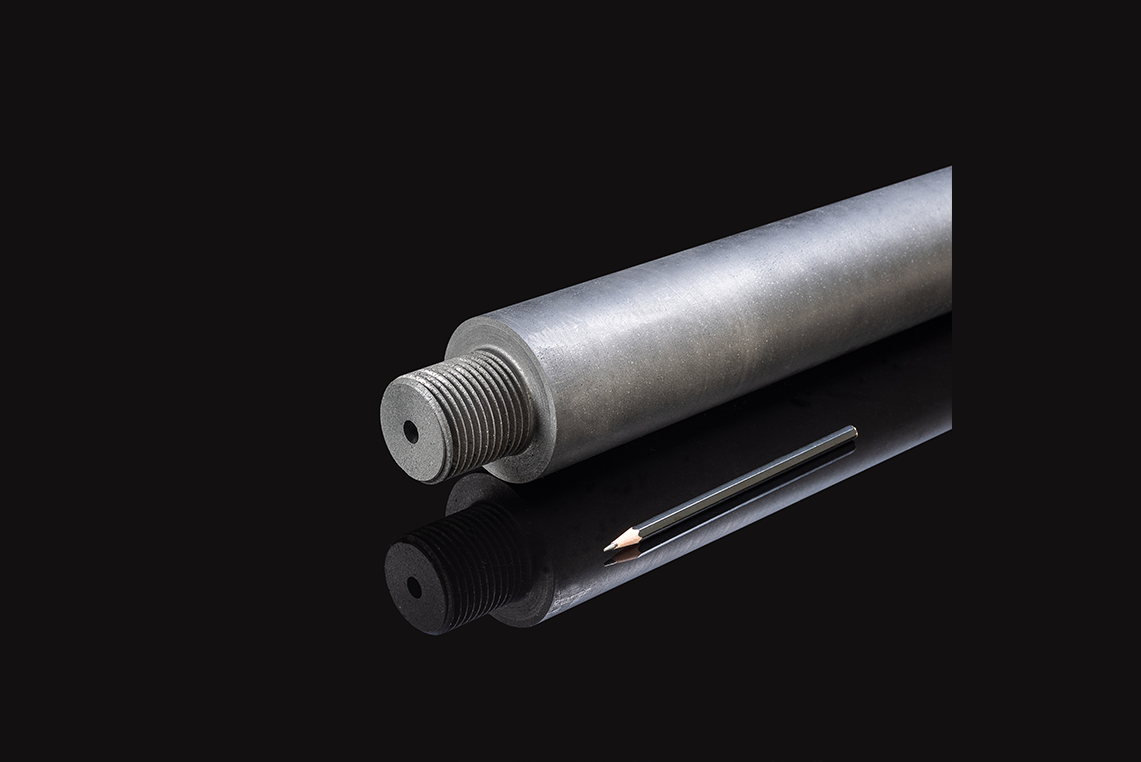

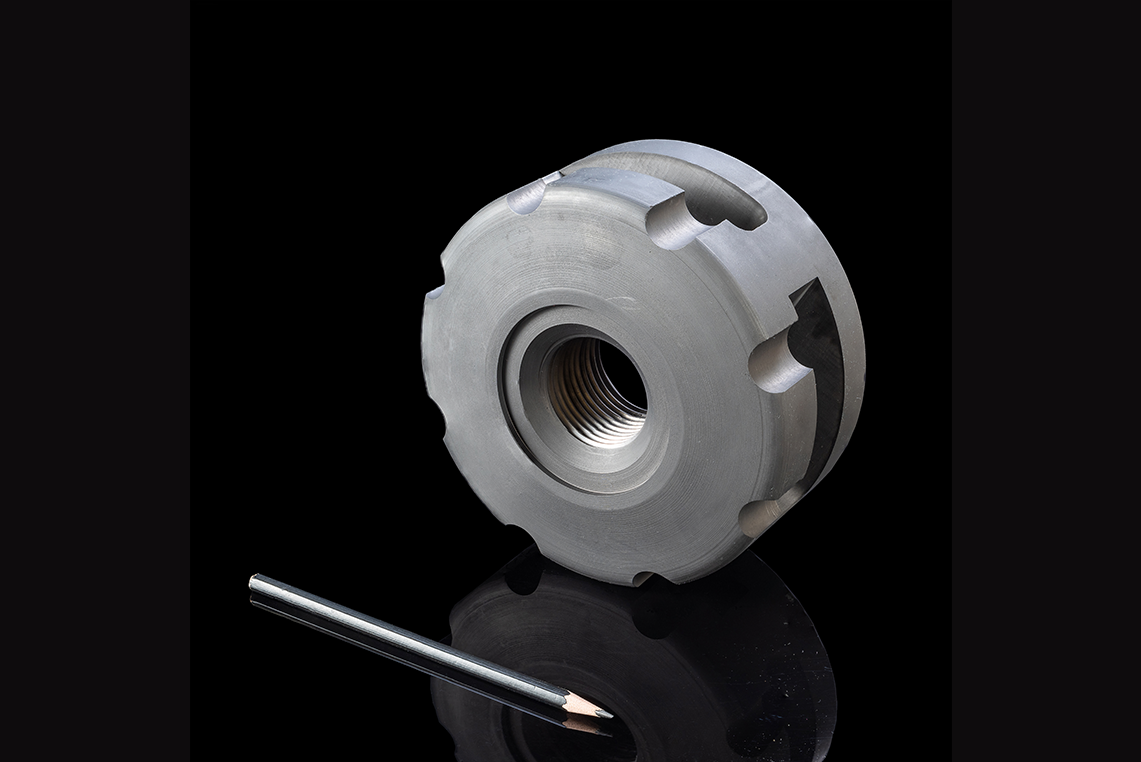

Global Graphite has India’s leading facility and Technologically ADVANCE machining centre with in-house IMPREGNATION facility to supply High quality SPECIAL AOT Treated of Graphite Rotor-shaft-baffle plates for longer life, lower oxidation, lower necking for aluminium degassing operations.

The aluminium nitrogen degassing process is used to remove dissolved gases, primarily hydrogen and nitrogen, from molten aluminium. This is important because these gases can cause defects in the final aluminium product. In this process, aluminium is typically treated with nitrogen gas in a degassing vessel.

The nitrogen reacts with the dissolved gases, forming bubbles that rise to the surface and are removed. Graphite rotor-shafts are commonly used in the aluminium nitrogen degassing process. Graphite is chosen for its high temperature resistance, low reactivity with molten aluminium, and good mechanical properties.

The Graphite rotor-shaft is immersed in the molten aluminium and rotates to create agitation, helping to facilitate the degassing process by breaking up the bubbles and promoting their rise to the surface. Overall, the combination of the aluminium nitrogen degassing process and the use of graphite rotor-shafts helps ensure the production of high-quality aluminium products with reduced gas content and fewer defects.

Email us to Get a Free Estimate